How Are Commercial Vehicle High-Brightness Headlights Manufactured?

Commercial Vehicle High-Brightness Headlights are designed to meet the demands of trucks, buses, and fleet vehicles that operate for long hours under varied road conditions. Unlike passenger car lighting, these headlights focus on stable output, consistent beam patterns, and durability suited for commercial use. For fleet operators and parts distributors, understanding how these products are made helps clarify purchasing decisions.

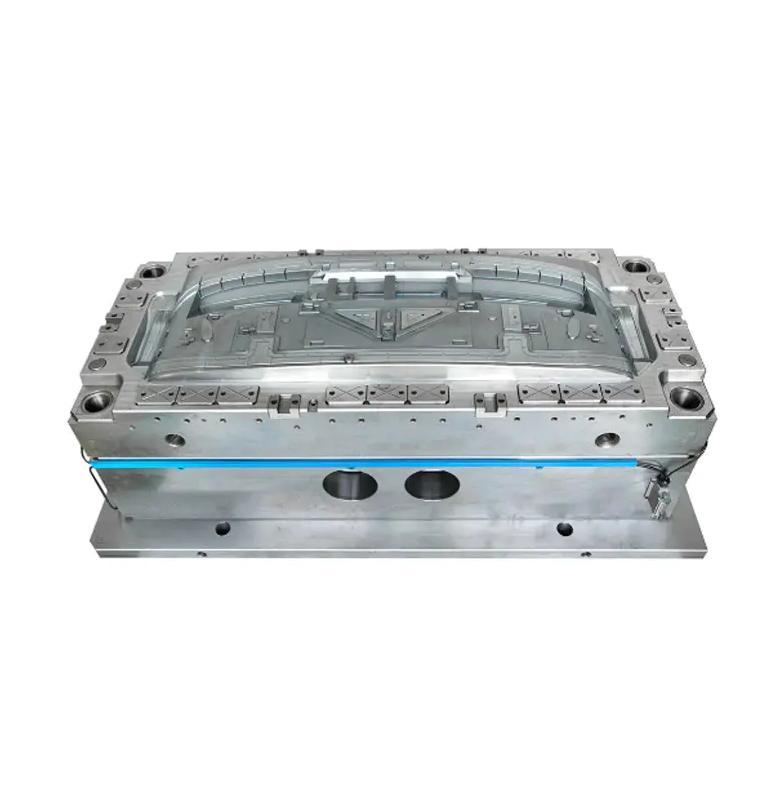

From a manufacturing perspective, Commercial Vehicle High-Brightness Headlights rely on a combination of precision moulds and controlled assembly processes. Injection moulds are commonly used for headlight housings and internal structural components. These moulds allow complex shapes to be formed with consistent dimensions, which matters when headlights must align accurately with vehicle frames and mounting points.

Commercial Vehicle High-Brightness Headlights Manufacturers pay close attention to housing stability. The housing must support the light source, lens, and internal components without distortion over time. Proper mould design helps manage material flow and cooling, reducing deformation after production. This stability supports consistent installation across large production batches.

Material selection also plays a practical role. Engineering plastics are widely used for headlight housings due to their resistance to vibration and temperature changes. When processed through well-designed injection moulds, these materials maintain shape and surface quality during repeated use. For buyers, this translates into fewer fitment issues during assembly or replacement.

Commercial Vehicle High-Brightness Headlights Manufacturers often design products to suit different vehicle categories within a fleet. Mounting positions, housing depth, and connector placement are adjusted based on vehicle platforms. This approach allows distributors to source headlights that integrate smoothly without major vehicle modifications.

Another aspect buyers often evaluate is durability during daily operation. Commercial vehicles experience continuous vibration and long driving cycles. Headlight components produced with balanced wall thickness and stable mould structures are less prone to loosening or deformation over time. This contributes to longer service intervals and reduced replacement frequency.

Commercial Vehicle High-Brightness Headlights serve as more than lighting components. They are functional parts shaped by mould precision, material stability, and process control. For fleets and distributors, selecting the right supplier means understanding how these factors come together in production.

By focusing on structural design, consistent moulding, and vehicle compatibility, Commercial Vehicle High-Brightness Headlights Manufacturers support reliable lighting solutions for commercial transportation. These considerations help buyers source products that fit operational needs without unnecessary complexity.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- الألعاب

- Gardening

- Health

- الرئيسية

- Literature

- Music

- Networking

- أخرى

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness