How Automotive Parts Molds Contribute to Production Efficiency

Automotive parts molds play a crucial role in the manufacturing process of various vehicle components, helping to shape and form materials into precise parts used in the automotive industry. These molds are designed to create high-quality components in large quantities, ensuring consistency and reliability for vehicles on the road. The application of automotive parts molds spans a wide range of vehicle components, from body panels to engine parts, and is essential for mass production.

Manufacturing Body Panels and Structural Components

One of the most common applications of automotive parts molds is in the production of body panels and structural components. These molds are used to form sheet metal or plastic into the desired shape for parts like doors, hoods, bumpers, and fenders. Precision in these molds is critical, as the parts must meet strict safety and aesthetic standards. The molds ensure that each part is uniform in size and shape, contributing to the vehicle's overall fit and finish.

Producing Engine and Powertrain Parts

Automotive parts molds are also heavily used in the production of engine components and parts for the powertrain, such as cylinder heads, engine blocks, and transmission housings. These molds are designed to handle high-pressure processes, as materials like aluminum, steel, and cast iron are often used to create durable, high-strength components. The ability to consistently produce these parts with tight tolerances is essential for engine performance and longevity.

Creating Interior and Safety Features

In addition to structural and engine components, automotive molds are used to produce parts for a vehicle's interior and safety systems. This includes items such as dashboard components, seat frames, airbags, and door handles. Molds for these parts must not only ensure functionality but also comfort and safety. The use of high-precision molds allows for the reliable production of these critical components, which must perform well under various conditions.

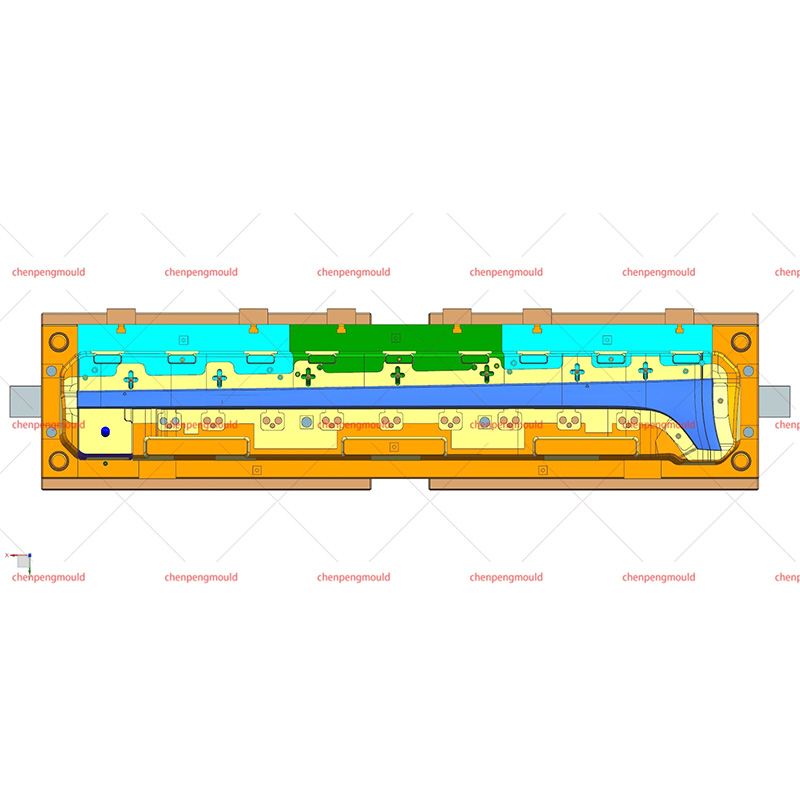

https://www.bumpermould.net/product/auto-parts-mould/plastic-injection-auto-mould-for-audi-a6-side-beam-a3-wheel-brow.html

https://www.bumpermould.net/product/auto-parts-mould/plastic-injection-auto-mould-for-audi-a6-side-beam-a3-wheel-brow.html

Steel For Cavity &. Core P20

Mould Base C40

NOs. of Cavity 1*1

Injection System Yudo 5 direct injection gates

Ejection System Ejector pins, angle lifters

Mould Standard OEM/HASCO

Mould Estimated Size 2200 x 950 x 1000mm

Mould Weight 12500KG

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Oyunlar

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness