Auto Lamp Mould Makes Manufacturing Feel Like Magic

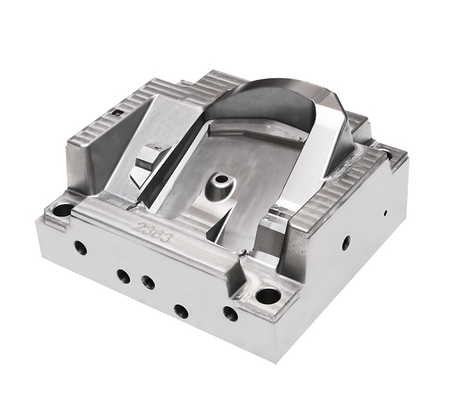

Precision and flexibility define Auto Lamp Mould in modern automotive production. Vehicle lamps no longer serve purely functional roles; their appearance complements overall design. Auto Lamp Mould provides the structure necessary for intricate shapes, ensuring smooth curves, uniform thickness, and consistent transparency across multiple units.

Design complexity increases when LED or adaptive lights are integrated. Auto Lamp Mould must accommodate varying thickness, internal features, and mounting points. Material flow during injection molding needs careful management to prevent defects such as air bubbles or surface irregularities. Engineers carefully plan gate locations, cooling paths, and reinforcement ribs to optimize results.

Production consistency benefits from Auto Lamp Mould features such as multi-cavity layouts. Producing multiple lamp components in a single cycle saves time while ensuring uniform quality. This consistency allows automotive assembly lines to maintain high throughput while reducing the risk of parts mismatch during assembly.

Durability of Auto Lamp Mould directly influences long-term efficiency. Metal fatigue, wear, and surface degradation are common challenges over repeated cycles. Regular inspection and timely maintenance prevent flaws in lamp surfaces and avoid downtime. Some moulds incorporate surface coatings to extend life and improve material release.

Designers often collaborate closely with mould engineers to achieve unique lamp styles. Concept cars, special editions, or customized trims require moulds that capture subtle curves and intricate details. This collaboration ensures that creative vision translates into manufacturable components, bridging design and engineering.

Efficiency improvements focus on cooling systems within Auto Lamp Mould. Correctly positioned channels reduce cycle times, prevent warping, and enhance optical clarity. Advanced simulation tools predict material flow and temperature distribution, allowing engineers to refine mould features before production begins.

Material choice impacts both mould design and lamp performance. Polycarbonate and acrylic retain clarity while handling thermal stress. Moulds must consider shrinkage, expansion, and part ejection to ensure lamps maintain precise dimensions after cooling. Even slight misalignment can affect vehicle lighting performance or aesthetic appeal.

Training of operators handling Auto Lamp Mould also improves efficiency and quality. Knowledge of material behavior, mould alignment, and proper maintenance prevents mistakes that can cause defects. Skilled operators contribute significantly to consistent production results.

Auto Lamp Mould remains a critical component in automotive manufacturing, supporting innovation, efficiency, and high-quality outcomes. This adaptability ensures that lamps not only function reliably but also contribute to vehicle style and performance.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Spiele

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness